3C Industry-FPC Full Line Vision Solution

2025-05-13

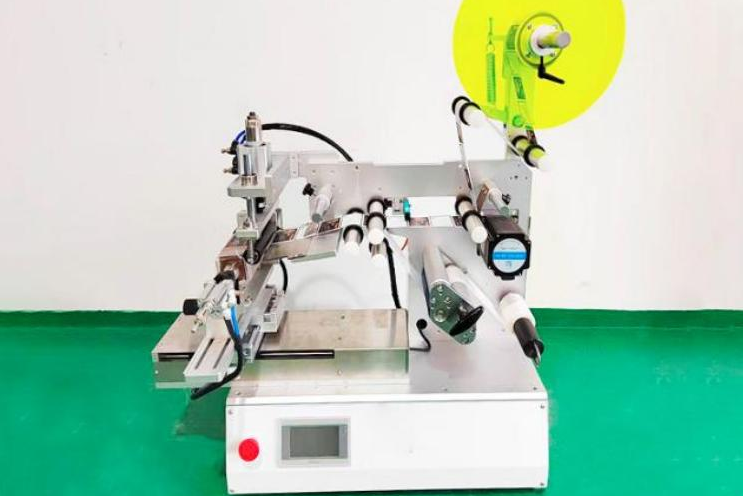

It is mainly used for appearance inspection of flexible printed circuit boards (FPC) and post-SMT (FPCA). It can be directly connected to the tray inspection, and the trays can be shipped directly after inspection. It can also automatically load and unload materials, which can replace the manual visual inspection and visual inspection mode with low efficiency and high false detection rate, realize machine replacement, reduce production costs, shorten production cycle and ensure product quality.

FPC appearance defect detection:

Gold finger indentation, foreign matter, gold finger oxidation, component missing/offset, copper leakage on the board, poor white oil, poor glue dispensing, TH hole offset, etc.

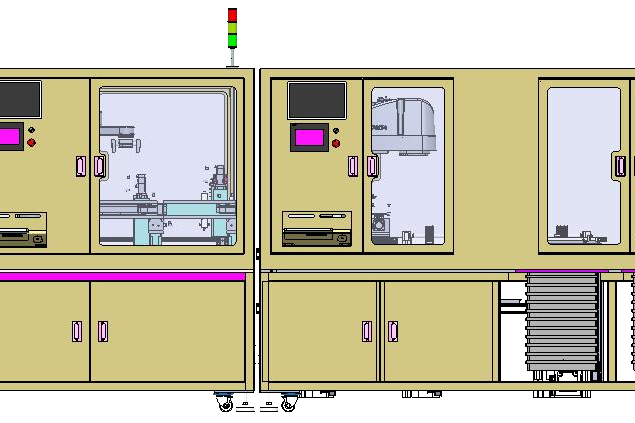

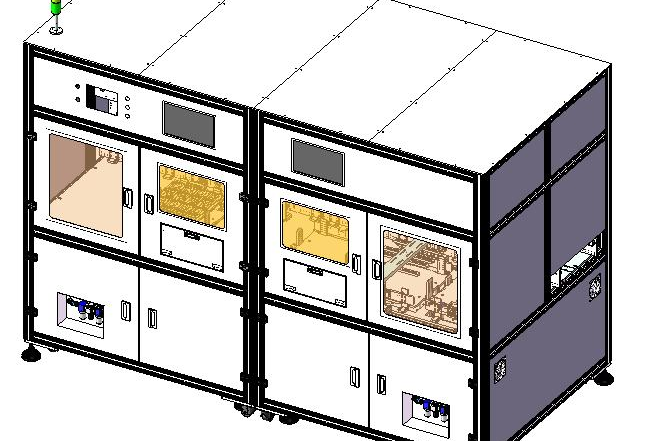

Main equipment and processes:

FPC loading machine → 2D inspection → 3D inspection → panel flipping machine → 2D inspection → NG recycling → FPC unloading machine.

In addition to redefining the device through a variety of traditional mathematical algorithms (covering grayscale, vector, pixel, color, perimeter, size, area, contour, coordinate, image comparison, barcode, text, etc.), the AI artificial intelligence technology algorithm is put into practical use, so that the software has a neural network system similar to the human brain, and the software has the ability to recognize, correct and deeply learn similar to the human brain.