How Does CCD Detection Equipment Help Factories Reduce Production Costs?

2025-09-09

When manufacturers think about automation, they usually focus on speed and quality. But there’s another hidden benefit of CCD detection equipment—cost savings. Let’s explore how this technology can directly improve a factory’s bottom line.

Cutting Down on Defects

Defects are expensive. Each defective product leads to rework, wasted materials, and potential delivery delays. Manual inspection often misses defects, which means more products escape into the supply chain.

With CCD detection machines, factories can:

-

Detect issues earlier in the process

-

Reduce defective output

-

Save materials and labor costs

In industries with thin profit margins, this makes a huge difference.

Lowering Labor Costs

Manual inspection requires a large workforce, especially in high-volume production. And let’s face it, workers get tired, which means inspection results are inconsistent.

CCD inspection equipment solves this problem by performing round-the-clock inspections with unmatched precision. That means fewer workers are needed for repetitive checking tasks, and human resources can be redirected to higher-value work.

Boosting Efficiency

Efficiency isn’t just about speed—it’s also about removing bottlenecks. Manual inspection often slows down production lines. But CCD systems can inspect thousands of products per hour, seamlessly integrated with automated production lines.

This helps factories meet tight deadlines and deliver to customers faster.

Supporting Global Competitiveness

When competing in international markets, buyers demand consistent quality and competitive pricing. A factory equipped with CCD detection equipment can promise both.

That’s why many global companies now work with Chinese CCD inspection equipment manufacturers, who offer:

-

Custom-designed systems

-

Competitive costs compared to Western brands

-

Strong after-sales support

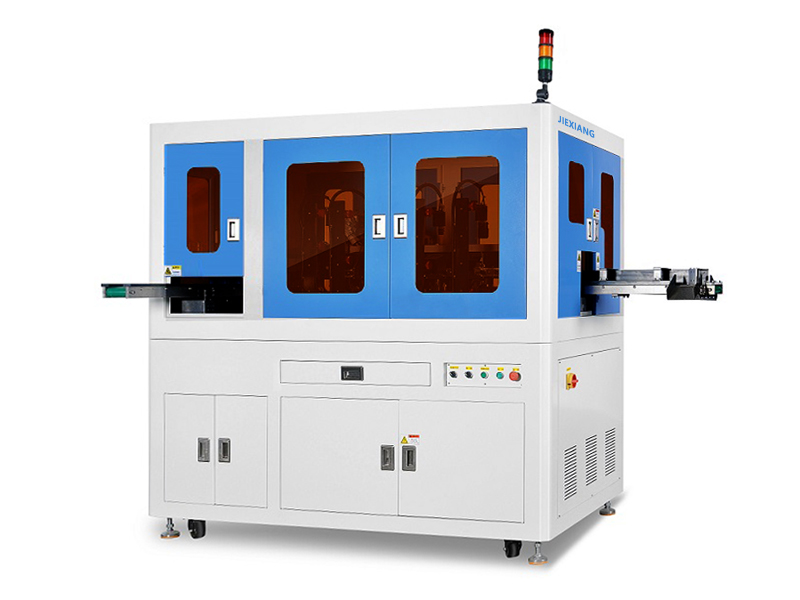

Kunshan Jiexiang, for example, has years of experience helping factories optimize production with intelligent CCD inspection machines.

Reducing costs doesn’t always mean cutting corners. With the right CCD detection equipment, factories can maintain top-level quality while lowering operational expenses. It’s a win-win strategy for any manufacturer aiming to grow in today’s competitive market.