How Vision AI Deep Learning Cover Inspection Machines Improve Product Quality in Manufacturing

2025-07-23

Challenges in Cover Inspection Today

Whether it’s smartphone covers, control panel surfaces, or medical device housings, manufacturers face a critical challenge: how to ensure consistent quality without slowing down production?

Traditional machine vision has its limits. It often can’t handle:

-

Variations in lighting

-

Slight changes in color or texture

-

Complex shapes or reflections

That’s where deep learning vision systems come in. Unlike rigid rule-based algorithms, these systems adapt and learn, identifying defects with unmatched precision.

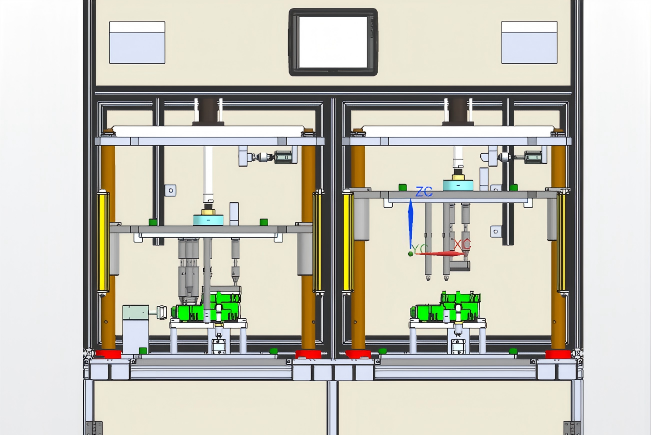

What Makes These Machines "Smart"?

Vision AI Deep Learning Cover Inspection Machines use neural networks trained on thousands of real product images. They don’t just detect if something is “off”—they understand how and why it’s off.

Some of the main features include:

-

Real-time image acquisition

-

Classification of multiple defect types

-

Automated pass/fail decisions

-

Self-learning capabilities over time

If you're still relying on human inspectors or old-fashioned cameras, this is a total game-changer.

Real Benefits You Can Count On

Let’s break it down. With a deep learning inspection system, you’ll benefit from:

-

More consistent defect detection

-

Reduced false rejects

-

24/7 automated operation

-

Easy integration with PLC or MES systems

Actually, many factories report ROI in less than 12 months after implementation. That’s not just efficient—that’s smart business.

Best-Fit Scenarios for Deep Learning Cover Inspection

These machines are perfect for:

-

Consumer electronics: phones, laptops, tablets

-

Medical device assembly: blister packs, casing

-

Automotive: dashboards, covers, switches

-

Home appliances: control panels, door trims

Anywhere you need 100% appearance inspection, these systems deliver.

Why Buy from a China-based AI Vision Supplier?

Let’s face it—China is leading the charge in industrial automation and AI hardware manufacturing.

With suppliers like Kunshan Jiexiang, U.S. buyers get:

-

Full customization based on their samples

-

Professional system design + training

-

Competitive pricing with no compromise on performance

-

Global logistics and English-language support

And hey, if you're wondering whether Chinese vision systems are reliable—just ask our hundreds of repeat buyers in North America!

Ready to Bring AI to Your Inspection Line?

You’ve probably seen the phrase “Industry 4.0” a million times, but here’s the truth: AI-based inspection is the real backbone of intelligent manufacturing.

So if your current inspection setup is slowing you down or letting defects slip through, now’s the time to upgrade.

Contact a professional Chinese manufacturer of Vision AI Deep Learning Cover Inspection Machines and future-proof your factory today.