How to Choose the Right Multifunctional Deburring Machine for Your Industry?

2025-08-05

Choosing the right multifunctional deburring machine can be tricky—especially with so many options on the market. The wrong machine can lead to production inefficiencies, higher operating costs, and inconsistent product quality.

But don’t worry—we’ve got your back. In this guide, we’ll walk you through the key considerations to help you select the best machine for your industry’s specific needs.

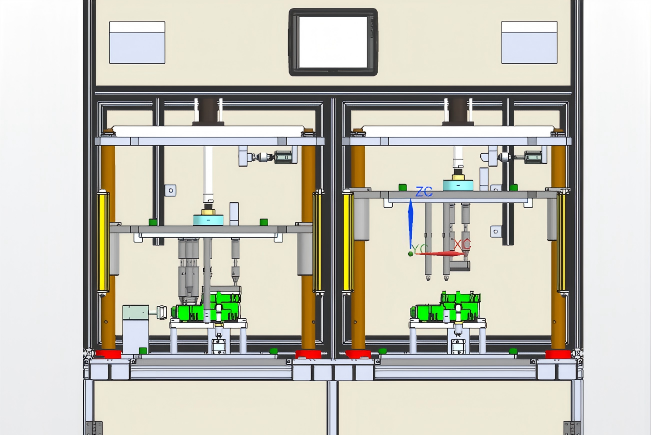

What is a Multifunctional Deburring Machine?

Before we dive in, let’s quickly recap what makes a deburring machine “multifunctional.”

These machines go beyond just removing burrs. They can perform:

-

Edge rounding

-

Oxide layer removal

-

Surface smoothing or polishing

-

Chamfering and grinding

The ability to perform multiple finishing steps in a single run makes them ideal for high-mix, high-volume production environments.

1. Consider the Type of Material You Process

Different industries work with different materials:

-

Automotive & aerospace: stainless steel, aluminum alloys

-

Electronics & semiconductors: copper, brass, soft alloys

-

Medical equipment: titanium, specialty steels

Make sure the machine is designed to handle your specific material hardness, thickness, and edge characteristics.

2. Know Your Surface Finish Requirements

Each application may demand different surface smoothness. For example:

-

Consumer electronics need visually perfect finishes

-

Welded parts require clean edges for coating

-

Machined parts need tight tolerances

Look for a deburring machine with adjustable brushing, grinding, or abrasive belt speeds, allowing you to meet different Ra values.

3. Think About Production Volume and Speed

Are you running low-volume prototyping or high-speed batch production?

If your production line is non-stop, you’ll need a heavy-duty machine with fast cycle times and automated loading/unloading options. On the other hand, small shops may prefer compact multifunctional models with manual operation to save space and cost.

4. Consider Automation and Smart Features

Today’s best-in-class machines come with:

-

Touchscreen control panels

-

Programmable job settings

-

Auto tool calibration

-

Vision systems for quality inspection

If your factory is heading toward Industry 4.0, integrating a smart deburring system with your MES or ERP can boost traceability and real-time production control.

5. Choose a Reliable Supplier (Don’t Skip This!)

This step is often overlooked, but it’s super important. A great machine from an unreliable supplier can lead to problems later—like delays in support, hard-to-find parts, or poor customization.

Here’s what to look for:

-

Experience in your industry

-

Customization capabilities

-

After-sales support

-

Real case studies or client testimonials

👉 Chinese manufacturers, especially companies like Kunshan Jiexiang Industrial Equipment Co., Ltd., are increasingly favored by U.S. buyers for their cost-effective pricing, technical customization, and global service.

So, What's the Bottom Line?

Choosing the right multifunctional deburring machine means matching the machine’s capabilities with your production needs, material type, and surface quality expectations.

And here’s the thing—buying the right equipment can dramatically reduce rework, improve product consistency, and boost your competitiveness.

Take your time to evaluate your options, run sample tests, and don’t hesitate to consult with professional suppliers in China who understand the unique demands of your industry.