How to Select the Right CCD Detection Equipment for Your Production Needs?

2025-09-02

Choosing the right CCD detection equipment can feel overwhelming. With so many models, features, and suppliers on the market, how can you be sure you’re making the right investment for your factory? Let’s break it down step by step.

Step 1: Identify Your Inspection Requirements

First, clarify what you’re inspecting. Are you checking:

-

PCBs and electronics for missing components?

-

Lithium battery packs for alignment and welding quality?

-

Precision parts for surface scratches?

By defining your inspection goals, you’ll avoid paying for unnecessary features.

Step 2: Look at Resolution and Accuracy

Not all CCD cameras are created equal. For microelectronics, you need high-resolution CCD systems that can detect the tiniest defects. For larger industrial components, medium-resolution systems may be more cost-effective.

The rule is simple: the higher the accuracy, the fewer defective products reach your customers.

Step 3: Evaluate Speed and Throughput

If your factory handles high-volume production, your CCD detection system must keep up. Look for:

-

High-speed cameras

-

Batch-mode or continuous inspection

-

Automation compatibility

The best systems won’t slow down your production line—they’ll actually speed it up by reducing bottlenecks caused by rework.

Step 4: Consider Software and Integration

CCD detection isn’t just about hardware. The software plays a huge role. Check if the system offers:

-

Easy-to-use interfaces for operators

-

Real-time defect reporting

-

Integration with MES or ERP systems

This ensures your inspection data becomes part of your digital factory.

Step 5: Choose a Reliable Supplier

Here’s the part that many companies overlook—supplier reliability. A good CCD detection machine is only as good as the support behind it.

Many global companies now work with Chinese CCD detection equipment manufacturers because they provide:

-

Customized engineering

-

Lower costs without sacrificing performance

-

Proven experience in multiple industries

-

Timely after-sales support

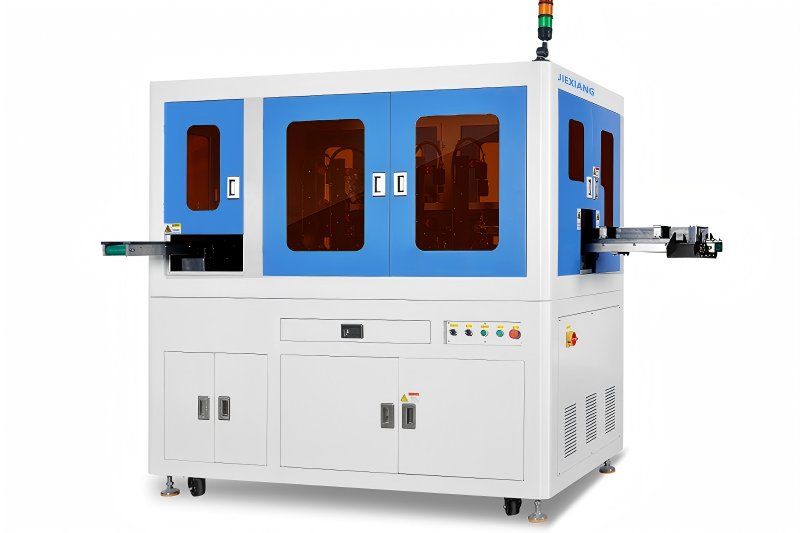

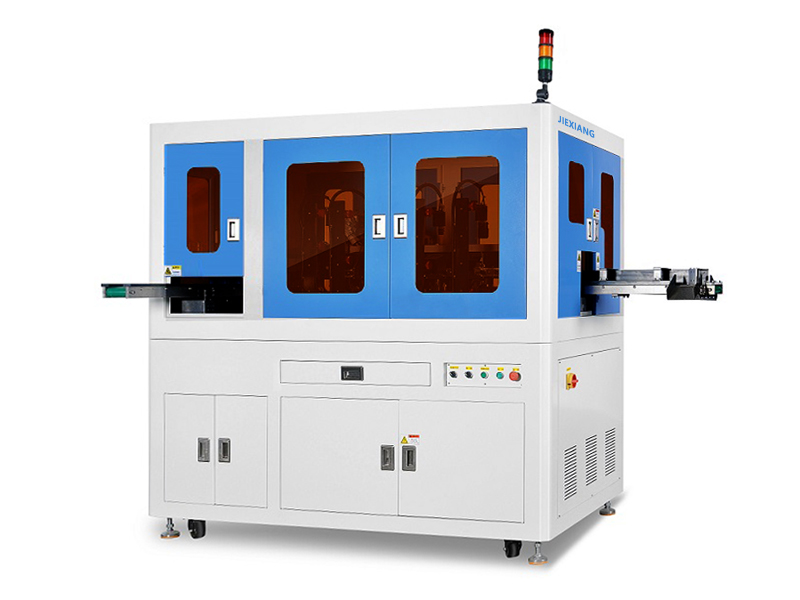

For instance, Kunshan Jiexiang has been delivering automated inspection equipment since 2009, serving industries from 3C electronics to semiconductors.

Selecting the right CCD detection equipment doesn’t have to be complicated. By defining your inspection needs, evaluating accuracy and speed, and choosing the right supplier, you can ensure your factory gets the most out of its investment.

Remember, the right CCD system is not just an inspection tool—it’s a way to boost quality, efficiency, and competitiveness in today’s global market.