Improve Surface Quality with a Multifunctional Deburring Machine

2025-07-28

In modern manufacturing, achieving a smooth and flawless surface finish is not just a matter of appearance but also functionality. That’s where a multifunctional deburring machine plays a crucial role. Whether you work with metal, plastic, or composite parts, these machines are designed to remove burrs, sharp edges, and unwanted residues, improving product quality and safety.

What Is a Multifunctional Deburring Machine?

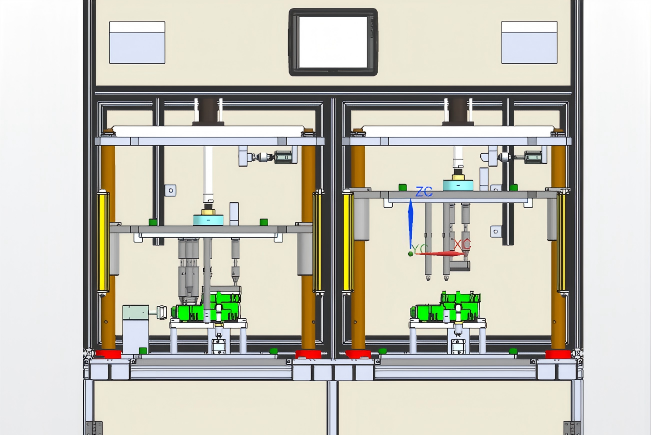

A multifunctional deburring machine is an advanced piece of equipment that integrates multiple finishing processes into one system. Instead of relying on manual sanding or filing, which is slow and inconsistent, this machine performs automatic deburring, edge rounding, and polishing all in one go.

Key functions often include:

-

Surface grinding and polishing

-

Edge rounding for safety and aesthetics

-

Oxide layer removal

-

Deburring of inner and outer contours

These machines are widely used in industries such as automotive, aerospace, electronics, and precision machining.

Why Is Deburring So Important?

Burrs may look small, but they can cause major issues:

-

Product defects leading to customer complaints

-

Assembly problems due to poor edge finishing

-

Safety hazards for workers or end-users

-

Reduced lifespan of mechanical components

Let’s be honest, nobody wants a product that feels rough or looks poorly finished. That’s why investing in a multifunctional deburring machine is a smart move.

Benefits of Using a Multifunctional Deburring Machine

By upgrading to an automated system, manufacturers enjoy:

-

Consistent quality across all parts

-

Faster production cycles

-

Reduced labor costs

-

Higher customer satisfaction

Actually, once you start using automated deburring, you’ll wonder how you ever managed with manual tools.

How to Choose the Right Deburring Machine?

When selecting a deburring solution, consider:

-

Material types and part sizes

-

Required surface roughness (Ra value)

-

Throughput and cycle times

-

Machine footprint and power requirements

It’s always a good idea to consult with a trusted Chinese supplier to customize the machine to your exact production needs.

Why Work with Chinese Manufacturers?

Chinese manufacturers are now leading global markets with cost-effective yet advanced deburring machines. Companies like Kunshan Jiexiang Industrial Equipment Co., Ltd. offer:

-

Tailor-made solutions for various industries

-

High-precision engineering and durable components

-

Global delivery and technical support

-

Competitive pricing without sacrificing quality

One of the reason many overseas buyers choose Chinese suppliers is because we provide flexible customization and fast after-sales service.

Final Thoughts

If your production line is struggling with quality issues caused by burrs or sharp edges, it’s time to switch to a multifunctional deburring machine. From metal sheet deburring to precision component finishing, these machines ensure smooth, safe, and reliable results.

Don’t wait—connect with a professional Chinese deburring machine manufacturer today and give your products the premium finish they deserve.