LCD screen surface defect detection (screen surface visual inspection solution)

2025-05-15

The LCD screen processing is relatively complicated. A qualified finished product requires at least three quality inspections. Currently, most of them are done manually under light, which is inefficient, slow, with inconsistent standards and a large number of subjective judgment factors.

The LCD surface defect detection solution introduces automated intelligent visual inspection equipment, which can detect defects such as oil, particles, bubbles, scratches, cracks, and edge collapse on the surface of the LCD screen, which not only improves the qualified rate of the production line, but also greatly improves production efficiency.

Introduction to the LCD screen surface defect detection solution

Detection range: oil, particles, bubbles, scratches, cracks, edge collapse and other defects.

Detection purpose: Improve the qualified rate of LCD screen production line.

Technical route:

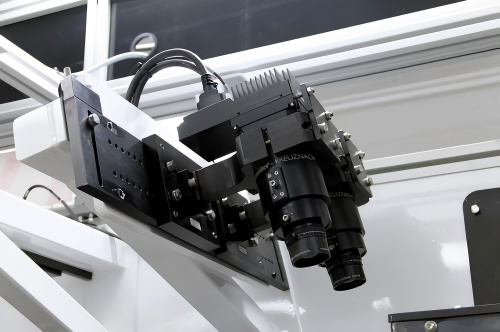

1 Trigger the linear array camera to realize image acquisition through the rotary encoder.

2 Run the control system to plan the camera scanning path and automatically adapt to the detection range.

3 Use image processing technology to detect defects in each image.

4 Splice defect images and draw the distribution map of the entire defect position.

5 Statistic the defect size and location and record them in the database.

6 Click the defect serial number to automatically pop up the original image defect to guide manual re-inspection.