New Energy Lithium Battery Industry Visual Defect Solution

2025-05-15

With the continuous development of the new energy industry, lithium batteries are playing an increasingly important role in the field of new energy. However, some visual defects such as foreign matter, scratches, bubbles, etc. are inevitable in the production process. These defects will seriously affect the quality and performance of lithium batteries, and even cause safety problems such as battery explosion and fire. Therefore, in order to improve the lean degree and quality control ability of lithium battery production process, some advanced visual inspection technologies and solutions need to be adopted.

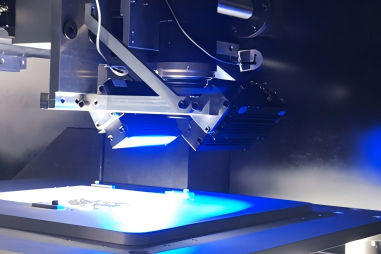

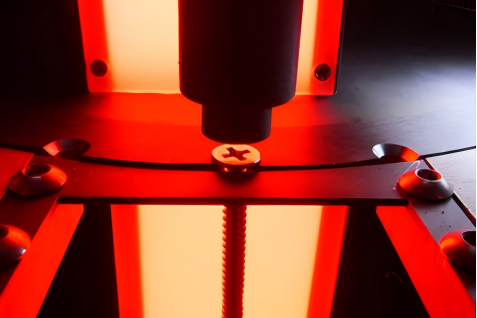

For the problem of visual defects in the production process of lithium batteries, machine vision technology is currently mainly used. Machine vision technology can use high-speed camera equipment and digital image processing technology to scan and analyze the surface of the product, so as to realize automatic detection, identification and classification of the product. By adopting high-precision machine vision inspection technology, non-destructive detection of defects in each manufacturing link of lithium batteries can be realized, which can not only greatly improve production efficiency, but also ensure product quality and meet the lean production and quality management requirements of the enterprise.

To realize the application of machine vision inspection technology, it is necessary to integrate multiple technologies, including hardware equipment, image acquisition and processing systems, algorithms and software. For example, it is necessary to use high-speed industrial cameras with high resolution, high frame rate and long life to capture real-time images of fast-moving batteries. At the same time, it is necessary to cooperate with efficient image processing technology to find the best algorithm to achieve fast and accurate identification of specific defects. In addition, it is necessary to develop corresponding software to analyze and count the inspection data to provide real-time feedback for production management and decision-making.

In summary, by adopting advanced machine vision technology, it is possible to efficiently and accurately detect and analyze visual defects in the production process of new energy lithium batteries, providing strong technical support for optimizing production processes and quality management. In the future, with the continuous development and application of intelligent manufacturing technology, the application of machine vision technology in the lithium battery industry will be more extensive, and it is expected to achieve fully intelligent production and quality management.