Upgrade Quality Control with Vision AI Deep Learning Cover Inspection Machines

2025-07-23

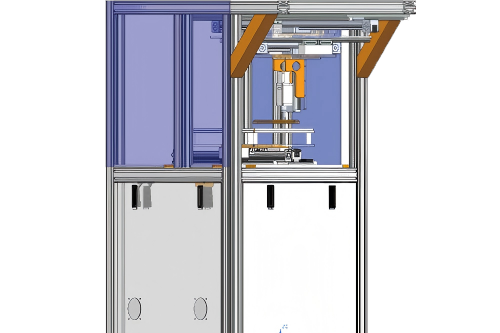

What Is a Vision AI Deep Learning Cover Inspection Machine?

In fast-paced production environments, especially in electronics, medical devices, and packaging, achieving flawless product quality is a huge challenge. That’s where a Vision AI Deep Learning Cover Inspection Machine steps in.

This machine uses advanced computer vision algorithms and deep learning models to inspect product covers—detecting defects such as:

-

Scratches and dents

-

Alignment errors

-

Color inconsistencies

-

Print misplacements

-

Shape deformation

With real-time defect detection and classification, these machines ensure zero-defect delivery, even at high speeds.

Why Traditional Inspection Methods Just Don’t Cut It

Let’s be honest: manual inspection is slow, inconsistent, and tiring. Even traditional rule-based machine vision systems can’t handle all the variations in today’s high-mix manufacturing.

Here’s the thing: deep learning doesn't rely on fixed rules. It learns from sample data, adapting to small variances that would normally trigger false rejects in old-school systems.

So, if you're tired of high false-positive rates or missing micro-defects, it might be time for an upgrade.

Key Benefits of Using Deep Learning Inspection Systems

By switching to AI-powered cover inspection machines, you’ll enjoy:

-

Higher inspection accuracy across varied products

-

Faster decision-making without human delay

-

Lower operational costs over time

-

Traceable inspection data for quality audits

And the best part? Once trained, these machines never get tired, distracted, or sloppy. Honestly, it’s like having the perfect inspector—working 24/7.

Industry Applications of Cover Inspection AI Systems

This technology is ideal for industries such as:

-

Smartphone and tablet assembly

-

Medical packaging lines

-

Automotive panel inspection

-

Consumer electronics casings

-

Home appliance parts

No matter how glossy, textured, or curved the cover is, deep learning can accurately detect micro-defects that traditional systems overlook.

Why Choose a Chinese Vision AI Equipment Manufacturer?

Chinese suppliers like Kunshan Jiexiang Industrial Equipment Co., Ltd. offer:

-

Customized inspection systems based on your sample parts

-

On-site training and integration

-

Global shipping and remote debugging

-

Competitive pricing and fast delivery

One of the reason many global factories work with China is because we deliver tailored, reliable automation—at a fraction of the cost.

Final Thoughts: Inspect Smarter, Not Harder

If you’re looking to reduce defect rates, improve brand image, and streamline inspection, a Vision AI Deep Learning Cover Inspection Machine is your best bet.

Ready to take the leap? Partner with a trusted Chinese supplier and bring your quality control into the era of smart automation.