Why Is Online Inspection Equipment 2D AOI Essential for Modern Electronics Manufacturing?

2025-09-16

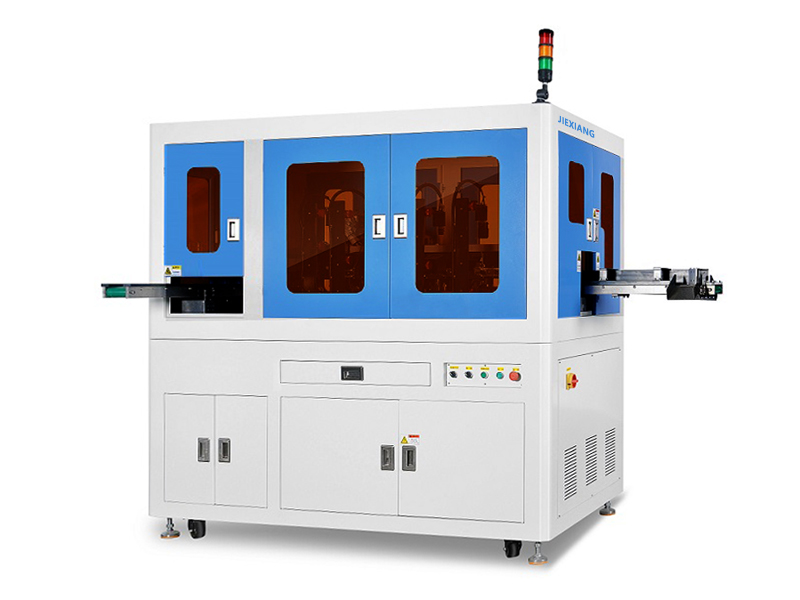

In today’s fast-paced electronics manufacturing industry, precision and efficiency are non-negotiable. As circuit boards become smaller and more complex, traditional manual inspection methods are no longer enough. This is where Online Inspection Equipment 2D AOI (Automated Optical Inspection) steps in, providing real-time quality control that keeps production smooth and reliable. Let’s explore why this technology has become indispensable for manufacturers worldwide.

What Is Online Inspection Equipment 2D AOI?

2D AOI, or Automated Optical Inspection, uses advanced cameras and imaging algorithms to detect soldering defects, component misalignments, missing parts, and other issues on PCBs. The “online” part means the inspection system is directly integrated into the production line, scanning each board in real time before it moves to the next step.

Unlike offline AOI, which requires separate handling and can slow down processes, online 2D AOI inspection equipment ensures that defects are identified immediately. This early detection prevents waste, reduces rework, and improves overall yield.

Key Advantages of Online 2D AOI Inspection

-

Real-Time Quality Control

The biggest advantage is speed. Defects are caught as soon as they appear, helping manufacturers react instantly. -

High Accuracy

Modern 2D AOI inspection equipment can detect even the tiniest soldering voids or bridging issues that the human eye might miss. -

Reduced Costs

By identifying defects early, you save money on wasted materials, reduce labor for rework, and prevent shipping defective products. -

Scalability

Whether you’re running a small production line or a high-volume factory, online AOI systems can adapt to your workflow.

Common Applications in Electronics

You’ll often find Online 2D AOI systems in industries like:

-

Consumer electronics (smartphones, tablets, wearables)

-

Automotive electronics (ECUs, sensors, safety systems)

-

Medical devices (PCBs for diagnostic and monitoring equipment)

-

Industrial electronics (controllers, automation modules)

Basically, wherever PCBs are produced at scale, AOI inspection has become a must-have.

Why Manufacturers Can’t Ignore It

Let’s be real: customers today expect flawless electronics. Even one tiny soldering issue can cause big problems down the line—think product recalls, warranty claims, or even safety risks. Online inspection equipment with 2D AOI acts like a safety net, catching problems before they leave the factory floor.

And honestly, once manufacturers experience the efficiency and confidence AOI brings, they don’t want to go back. It’s like switching from a flip phone to a smartphone—you’ll never look back.

As electronic assemblies grow smaller but more powerful, the role of online 2D AOI inspection equipment will only get bigger. It ensures precision, improves efficiency, and safeguards brand reputation. For manufacturers looking to stay competitive in global markets, investing in this technology is no longer optional—it’s essential.