Why Should Manufacturers Invest in Non-Standard Automatic Material Feeding Machines?

2025-10-09

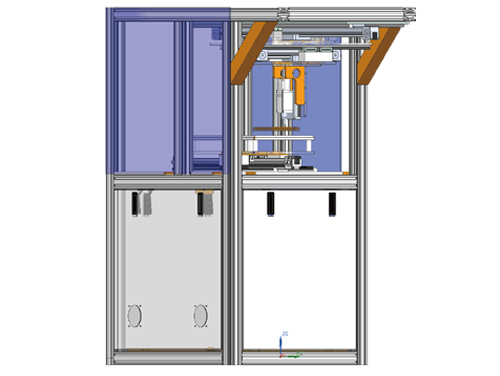

If you’re running a production line, you may wonder: Is investing in a non-standard automatic material feeding machine really worth it? The answer is yes, especially when your production process requires flexibility, precision, and efficiency.

The Advantages of Non-Standard Feeders

-

Higher Production Efficiency – Automated feeding eliminates downtime caused by manual material handling.

-

Consistent Quality – Accurate feeding reduces errors and improves product consistency.

-

Cost Savings – Less reliance on manual labor lowers operating costs.

Manufacturers often overlook how much time and resources are wasted in manual or semi-automatic feeding processes. Non-standard feeders solve this problem effectively.

Applications Across Industries

Non-standard automatic material feeding machines are widely used in:

-

Electronics assembly lines

-

Automotive parts production

-

Packaging and labeling lines

-

Custom manufacturing requiring unique material sizes

The versatility of non-standard feeders ensures that even unique production challenges can be met efficiently.

How to Choose the Right Machine

When selecting a non-standard automatic material feeding machine, consider:

-

Material types and sizes

-

Required feeding speed and capacity

-

Integration with existing production lines

-

Supplier support and customization options

Many companies now rely on Chinese manufacturers and suppliers because they offer cost-effective solutions tailored to specific production needs.

Investing in a non-standard automatic material feeding machine can transform your production line. With improved efficiency, reduced labor costs, and greater accuracy, these machines are a practical choice for any manufacturer aiming to stay competitive.