Why a Multifunctional Deburring Machine is a Must-Have for Modern Factories

2025-07-28

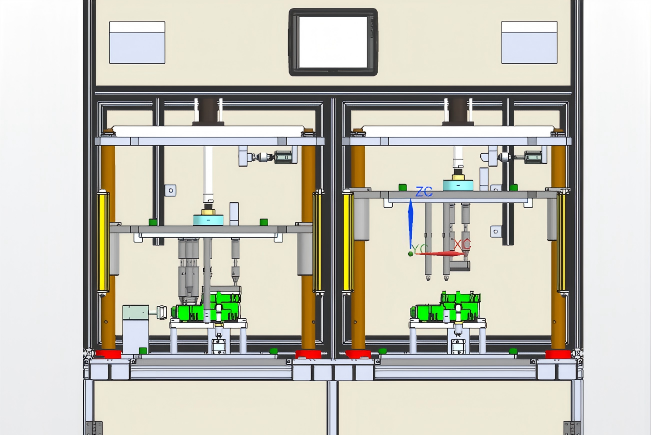

In industries where precision and surface quality matter, the multifunctional deburring machine has become a game-changer. Whether it’s automotive, aerospace, or electronics, this equipment ensures smooth, safe, and defect-free parts. But why is it such a big deal? Let’s dive in.

The Role of Deburring in Manufacturing

Deburring might sound like a minor step, but it’s critical for:

-

Removing sharp edges that can cause safety hazards

-

Improving assembly quality and avoiding misalignment

-

Enhancing product aesthetics and durability

-

Preventing mechanical failures due to burr-induced friction

Manual methods, like sandpaper or files, are not only labor-intensive but also inconsistent. A multifunctional deburring machine takes this burden away by providing automated and repeatable results.

What Makes a Deburring Machine “Multifunctional”?

Unlike single-purpose tools, a multifunctional deburring machine integrates several finishing techniques:

-

Flat surface deburring

-

Edge rounding and chamfering

-

Oxide layer removal

-

Polishing or brushing for a glossy finish

This versatility means one machine can handle a wide range of materials, including stainless steel, aluminum, titanium, and plastics.

Key Benefits of Automated Deburring

Switching to automated deburring offers:

-

Faster throughput with fewer production bottlenecks

-

Uniform surface quality across all parts

-

Lower labor costs and minimal rework

-

Extended tool life by eliminating manual errors

Honestly, once you see how efficient these machines are, you’ll never go back to manual processes.

Industries That Rely on Deburring Machines

Multifunctional deburring machines are widely adopted by:

-

Automotive plants for chassis and body parts

-

Aerospace manufacturers for high-tolerance components

-

Metal fabrication workshops for sheet metal finishing

-

Electronics and PCB producers for burr-free boards

-

Medical equipment makers for precision surgical tools

These industries demand consistent precision and reliability, which only automated solutions can provide.

How to Select the Right Machine?

When evaluating a multifunctional deburring machine, consider:

-

Material type and thickness

-

Surface finish requirements (Ra value)

-

Production volume and speed

-

Machine footprint and power needs

-

After-sales service and spare part availability

And here’s a tip: always request sample tests before purchasing. It’s kinda like test-driving a car—you need to know what you’re buying.

Why Work with a Chinese Manufacturer?

Chinese suppliers have gained global recognition for delivering cost-effective and high-performance deburring equipment. Companies like Kunshan Jiexiang Industrial Equipment Co., Ltd. offer:

-

Custom machine designs tailored to your production line

-

Comprehensive technical support and training

-

Fast delivery and global service

-

Competitive pricing with top-notch quality

One of the reason global factories trust Chinese suppliers is because we balance innovation with cost efficiency.

Final Thoughts: Ready to Upgrade?

If you’re struggling with inconsistent part finishing or high labor costs, it’s time to consider a multifunctional deburring machine. It’s not just about better surfaces; it’s about achieving higher productivity, safety, and customer satisfaction.

Reach out to a reliable Chinese manufacturer today and take your production quality to the next level.