Why does the manufacturing industry need machine vision inspection equipment?

2025-05-15

On the production line, product identification, barcode recognition, product inspection, appearance size/defect inspection, and highly repetitive and intelligent work such as product quality inspection can only be completed by manual inspection. Such measurement and judgment will not only produce errors and mistakes due to fatigue and individual differences, but also such inspection procedures will not only increase huge labor costs for enterprises, but also cannot guarantee 100% inspection pass rate (i.e. "zero defects").

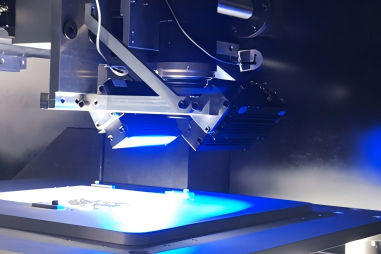

In addition to saving a lot of labor resources, the use of machine vision systems can also perform high-precision, high-efficiency, and high-stability real-time inspection, analysis, and calculation on the inspected items to determine whether the inspected items are qualified, and then automatically remove defective products.

1. Higher accuracy

The human eye is limited by physical conditions and is also affected by factors such as subjectivity and physical energy, and accuracy cannot be guaranteed. Machines are not subject to subjective control, and as long as there is no difference in parameter settings, multiple machines with the same configuration can guarantee the same accuracy.

2. Reduce labor costs

Manual inspection is inefficient. Machine vision inspection is much faster, capable of inspecting hundreds or even thousands of components per minute, and can work continuously for 24 hours.

3. Improve productivity

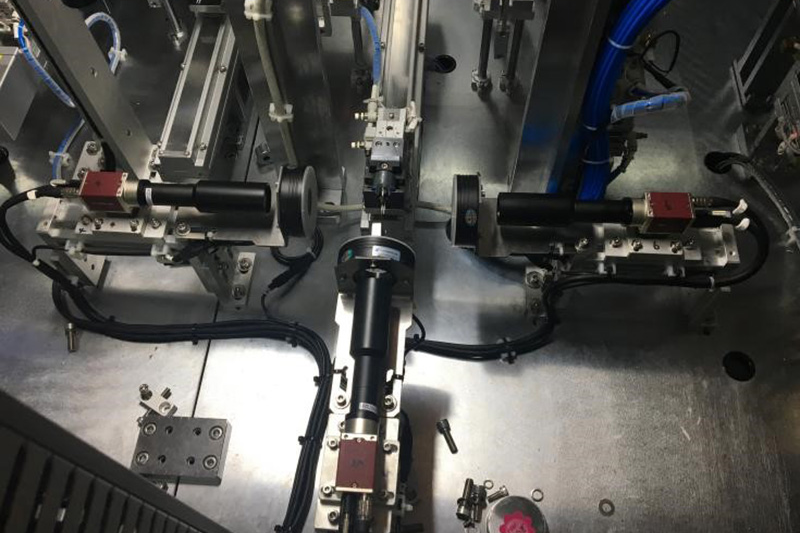

Measure data and generate reports after measurement without manually adding them one by one, avoiding contact damage when manual inspection must contact the workpiece; machine vision inspection equipment can adapt to overcome various harsh and dangerous environments, and complete inspection work well in occasions where human vision is difficult to meet the needs.

4. Reduce maintenance costs

Machine vision inspection equipment can measure multiple technical parameters at a time through multi-station measurement methods, such as the contour, size, appearance defects and product height of the product to be inspected. And it is more efficient than manual inspection, has low technical requirements for operators, and has a long service life of equipment. In the long run, the cost of machine vision inspection is lower.

5. More objective and stable

During manual inspection, the inspection results will be affected by personal standards, emotions, energy and other factors. However, the machine strictly follows the set standards, and the inspection results are more objective, reliable and stable.

In general, compared with manual inspection, machine vision inspection has the characteristics of objectivity, non-contact and high precision. Especially in the field of industrial production, it has strong application value in repetitive and mechanical work. For enterprises, it not only ensures the stability of product quality but also improves product competitiveness.