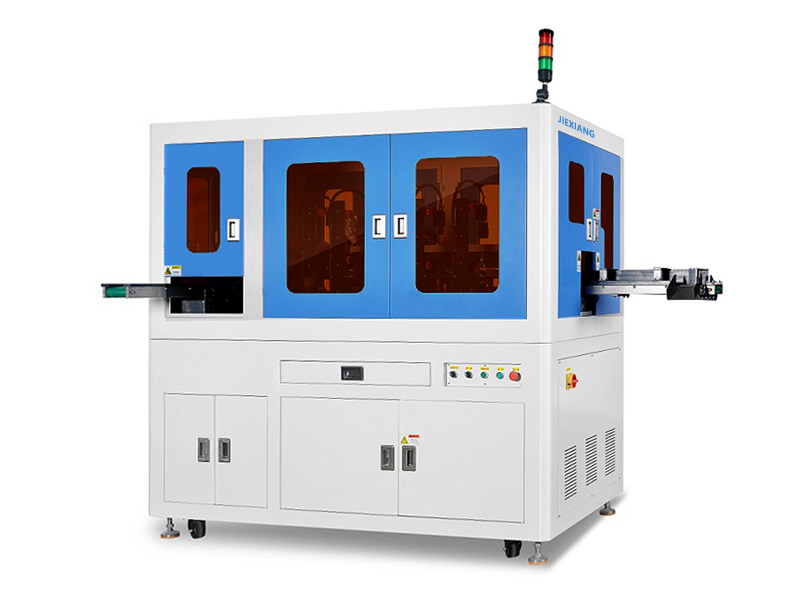

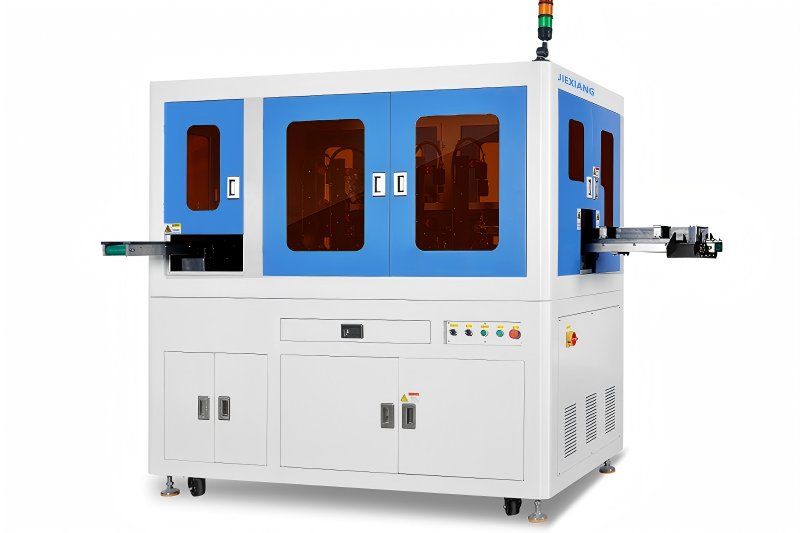

CCD detection equipment

Instead of manual single repetitive testing work, the product can be fully inspected automatically, which improves the testing efficiency, ensures the accuracy of the testing process, and enhances the competitiveness of the enterprise.

Equipment function: Replace manual single repetitive testing work, conduct 100% automatic full inspection of products, improve testing efficiency, ensure the accuracy of the testing process, and enhance corporate competitiveness.

Equipment principle: Use CCD measurement technology to quickly obtain product multi-faceted feature dimensions, real-time measurement data, and edge contour feature lines at different locations. Use powerful software algorithms to process feature detection on the product reflected in the CCD image, calculate relevant dimensions, and make accurate judgments on product dimensions.

Equipment function: The equipment consists of an automatic loading system, a transmission positioning system, an automatic measuring system, an automatic sorting and unloading system, an intelligent measurement and control system, and a computer data processing system. It can automatically measure the inspection items required by customers, sort out qualified and unqualified parts according to the measured values of the workpiece, and perform statistical analysis on the measurement data.

Equipment requirements: Work continuously for 24 hours in an ambient temperature range of 5-40°C, and be able to keep the equipment reliable and running smoothly.

Equipment features: The indexing plate rotates 360 degrees and seamlessly connects to the glass plate. Integrated detection. One device can match the production capacity of multiple traditional devices, saving costs, improving work efficiency, avoiding secondary damage to products, and improving product quality. Product replacement is fast, the detection range is wide, and the accuracy is high.

Compared with manual inspection, CCD visual inspection equipment has the following advantages:

1.Objective test results are more accurate and reliable. CCD visual inspection will not be affected by factors such as operator fatigue, responsibility and experience. Traditional human eye inspection has a fatal flaw, which is the subjectivity brought by emotions. The test results will change due to the worker's mood. The machine has no emotions, so the test results are naturally accurate and reliable.

2.Highly repeatable CCD vision inspection equipment does not get tired, in contrast to the human eye which will see a slightly different product each time it inspects it, even if the product is exactly the same.

3.High-speed CCD vision inspection can inspect products faster, especially when inspecting high-speed moving objects, such as products moving on a production line.

4.Low cost and high efficiency, CCD visual inspection equipment can undertake the tasks of several people, and the machine does not need to stop, will not get sick, and can work continuously, so it can greatly improve production efficiency.