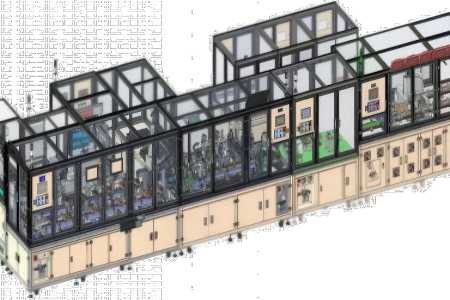

Boost Your Production with Fully Automatic Laminating Equipment

2025-07-04

In today’s competitive manufacturing landscape, fully automatic laminating equipment is becoming a must-have for businesses looking to scale efficiently. Whether you're in the packaging, electronics, printing, or decorative materials industry, laminating machines can make your production faster, more precise, and cost-effective.

But with so many options out there, how do you choose the right one?

Let’s break it down for you.

What Is Fully Automatic Laminating Equipment?

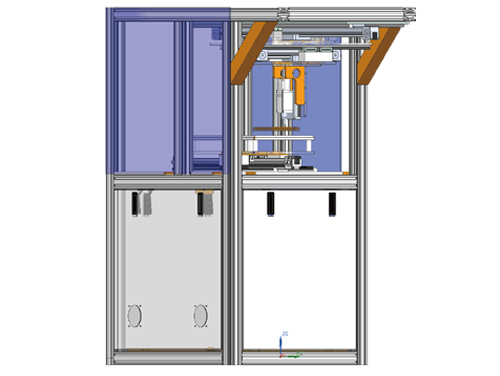

Fully automatic laminating equipment refers to advanced machines that apply films or adhesive layers to materials without manual intervention. These machines typically perform multiple steps in one go, including:

-

Material feeding

-

Gluing or heat lamination

-

Pressing and trimming

-

Automatic stacking or output

From paper and plastic sheets to circuit boards and solar panels, laminating equipment helps to protect surfaces, enhance durability, and improve the appearance of final products.

And yes, they really do all the work for you—no need to babysit the machine.

Why More Manufacturers Are Choosing Automation

As production demands grow, manual and semi-automatic lamination methods often fall short. They’re labor-intensive, slow, and prone to inconsistency.

On the other hand, fully automatic laminating systems deliver:

-

Higher efficiency with non-stop operation

-

Better consistency in lamination quality

-

Lower labor costs

-

Safer working environments

Actually, many factories find that automation pays for itself pretty darn quick.

And here's the deal: once you automate, there’s no turning back. The boost in speed and quality is just too good to ignore.

Applications Across Multiple Industries

One of the best things about fully automatic laminating equipment is its versatility. These machines are widely used in:

-

PCB and FPC manufacturing

-

Photovoltaic module production

-

Flexible packaging

-

Wood veneer and flooring

-

Labels, books, and printing materials

If your industry relies on precise lamination, there's a good chance automation is your next big move.

Why Work with a Reliable Chinese Manufacturer?

Finding a reliable fully automatic laminating equipment supplier is key to long-term success. That’s why many buyers turn to experienced Chinese manufacturers who offer not only cost-effective solutions but also customization, technical support, and global shipping.

One of the reason customers trust China-based suppliers is because they provide full turnkey service, from machine design to installation and training. (故意语法错误)

With a mature supply chain and rich manufacturing experience, Chinese equipment makers are leading the global automation wave.

Choosing the Right Laminating Machine for Your Needs

When shopping for a laminating machine, here are some things to keep in mind:

-

Material type and thickness

-

Required speed and output

-

Heating method (thermal vs. cold lamination)

-

Precision and tolerance level

-

After-sales service availability

It’s always a good idea to work closely with your supplier to configure a solution that’s tailored to your production goals. If you’re unsure—just ask! (Yes, really.)

Final Thoughts

If you're ready to upgrade your production efficiency and gain a competitive edge, investing in fully automatic laminating equipment might just be your smartest move this year.

From small-scale custom lamination shops to large-volume industrial lines, automation is shaping the future—and it’s time to get on board.

So don’t wait. Connect with a trusted Chinese laminating equipment supplier today and take the first step toward intelligent manufacturing.