How a Non-standard Automatic Feeding Machine Can Transform Your Production Line

2025-07-15

The Problem with Manual and Standard Feeding

Let’s be real—manual feeding is messy, inconsistent, and slow. Even standard feeding machines struggle with non-uniform parts or high-speed demands. In industries like electronics assembly or medical device production, you just can’t afford delays or mistakes.

That’s where a non-standard automatic feeding machine saves the day.

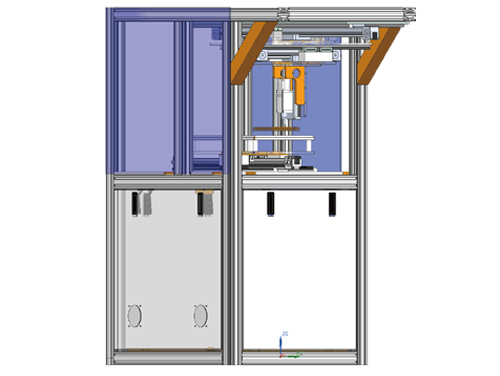

What Makes Non-standard Feeding Equipment So Effective?

These machines are fully tailored to:

-

Match your component geometry

-

Sync perfectly with PLC or robotic arms

-

Handle fragile or special parts with care

-

Reduce operator fatigue and manual intervention

Imagine an entire shift without feeding errors or stoppages. Sounds good? That’s what this equipment is designed for.

Real Benefits for Real Production Lines

When you invest in customized automatic material feeders, you get:

-

Shorter cycle times

-

Better part alignment and positioning

-

Higher machine uptime

-

Flexible feeding for multiple product models

Plus, modern non-standard feeders include sensors, alarms, and smart diagnostics that alert you before problems happen.

It’s kinda like having a feeding assistant that never gets tired or distracted.

Why U.S. Buyers Prefer Chinese Feeding System Suppliers

Chinese automation equipment manufacturers have made massive strides in both technology and customer service. For U.S. factories, they offer:

-

Full OEM/ODM capabilities

-

Rapid prototyping and precision machining

-

Remote debugging and training support

-

Affordable price without compromising quality

Needless to say, you’re getting high-end automation without blowing your budget.

What to Look for in a Custom Feeding Solution

Before placing an order, consider:

-

Your feeding volume per minute

-

The complexity of part orientation

-

Whether integration with robots is needed

-

After-sales service and local support in the U.S.

And hey, if you’re not sure, just reach out to the supplier—they’ll help you spec out the perfect system.

Ready to Automate Smarter?

Non-standard automatic feeding machines are changing the way factories operate. If you're looking for better reliability, faster speeds, and smarter integration—don’t settle for standard.

Work with a trusted Chinese supplier who understands your workflow, and bring efficiency to a whole new level.