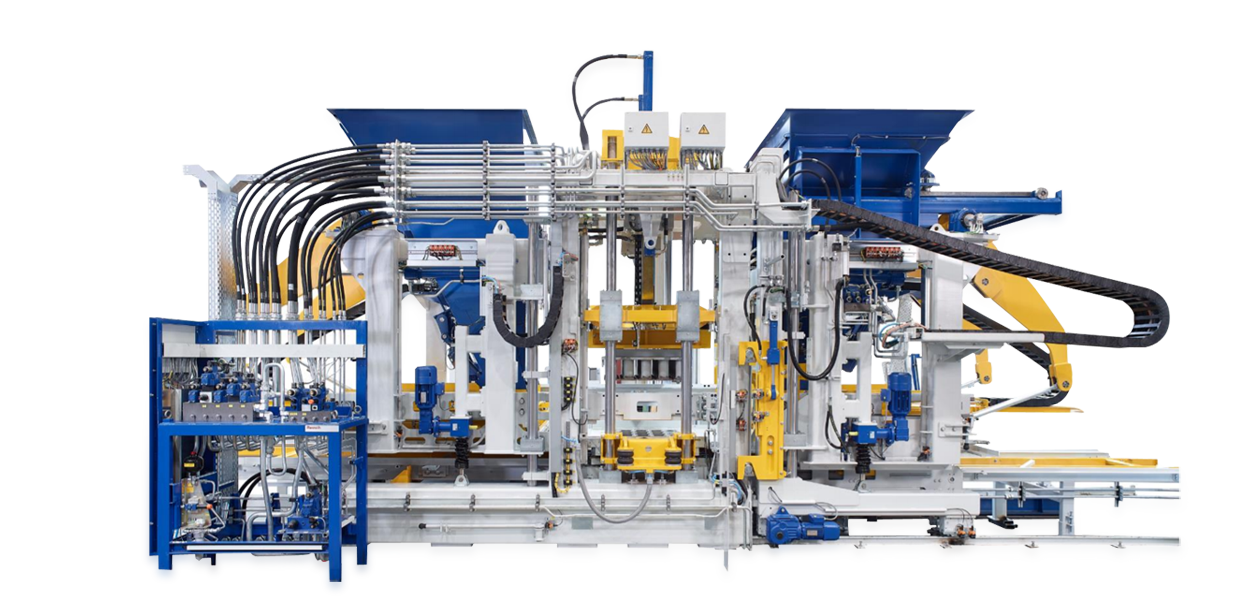

Hanging screw detection and screening machine

Hanging screw inspection and screening machine is a visual inspection and screening equipment specially developed for the inspection and screening of long-stem screws. It is mainly used to replace manual size inspection, appearance inspection, and defect inspection of various types of long-stem screws that require high-precision inspection. It can automatically complete the loading, inspection, identification, and screening work, greatly improving the inspection accuracy and speed of the appearance size of long-stem screws, reducing the cost of manual inspection, and inspecting many types of long-stem screws and nuts, covering a wide range of inspection items. It is an ideal high-precision long-stem screw appearance defect inspection equipment.

Surface visual defect detection equipment Hanging screw detection and screening machine principle:

Using CCD image control system as the main control unit, using displacement and visual sensing technology, according to the screw parameters, automatically completes loading, detection, and identification, and finally automatically selects good and defective products.

Technical features of the surface visual defect detection equipment double-disc screw nut inspection machine:

● Non-standard customization to meet different needs of users

● Automatic CCD visual inspection to reduce manual inspection costs

● High inspection accuracy, the highest inspection accuracy is ±0.01mm

● Many inspection items and wide inspection range

● Fast inspection speed, the fastest inspection speed is 180 pieces/min

● High technological content, advanced technology, high precision, good stability, reliable quality and convenient operation.

● Smooth and accurate inspection and assembly process, no vibration, impact and other undesirable phenomena.

● Data display, automatic judgment of "qualified" or "unqualified".

● Adopting German CCD high-resolution camera, the quality reliability is good.

● It can be equipped with automatic conveying device and automatic assembly device to complete the automation of feeding and unloading.

Surface visual defect detection equipment hanging screw detection and screening machine can screen objects:

Long-stem screws that require high-precision size and appearance defect detection. It can be reasonably customized according to the shape and size of the object.

Surface visual defect detection equipment hanging screw detection and screening machine detection items:

Cracks, burrs, head text/shape, length, diameter, whether there is a cut tail, pinhole concentricity/roundness, whether there are teeth on the screw nut, inner and outer diameters of the screw thread, screw thread pitch, screw thread angle, poor thread rolling, bottom shape, tailing, bending, tail cut groove, multi-section height/width/thickness, chamfer/angle, number of teeth, surface characteristics, surface flaws, marks, surface defects, etc.